AMSYS GmbH & Co. KG, Mainz, July 2023 –With the LDE / LME / LMI series, AMSYS now also offers ultra-low pressure sensors from a pressure range of only 25 Pa, which are based on the patented micro-flow technology from First Sensor. Here, the thermal mass flow measurement has been miniaturized and integrated into a microstructured silicon chip measuring only 2 x 2 mm².

Their high sensitivity combined with good overpressure behavior predestines the LDE/LME/LMI sensors from AMSYS for measuring volume flows. The sensors are mainly used in medical technology as well as in ventilation and air conditioning technology. For reasons of efficiency, the obstruction required for volume flow measurement should be as low as possible, which places increased demands on the differential pressure sensors due to the low pressure drop – ideal requirements for the new micro-flow ultra-low pressure sensors from AMSYS.

The operating principle of thermal mass flow measurement is based on a heating element that heats the gas in a small opening between the two pressure connections. Pressure differences cause an asymmetric temperature gradient to form in the connecting channel due to the gas flow. This is detected by temperature sensors on both sides of the heating element and converted into a linearized differential pressure signal.

The advantage of mass flow measurement is its extremely high sensitivity for the smallest pressure differences. This allows measuring ranges of 0 … 25 Pa or +/-25 Pa with simultaneous high overpressure resistance of up to 2 bar. The solution via a tiny, microstructured connection channel in a silicon die minimizes unwanted flow by increasing the pneumatic impedance to about 200 kPa/(ml/s). This is a factor of 1000 over comparable sensors and makes AMSYS ultra-low pressure sensors robust against dust and interference from long tubing.

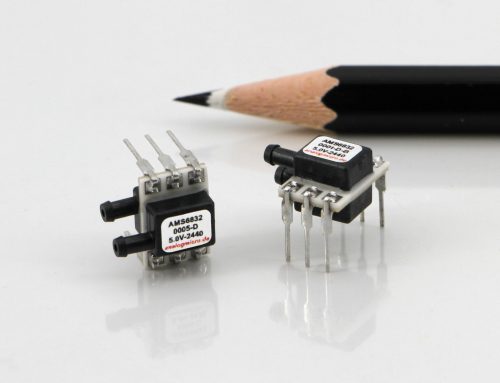

The very small SMD housing of the LME / LMI sensors is optimized for direct manifold mounting. The LDE series offer hose connections for SMD or DIP mounting as an alternative.

Available output signal is a 16bit I²C (LMI series) or SPI and 0.5 … 4.5 V analog signal (LME/LDE series). The value of the integrated temperature sensor can also be queried via the digital outputs. During production, the low-pressure sensors are individually linearized, calibrated and temperature-compensated. Thus, no additional circuitry, such as a compensation network, is required.

AMSYS offers the Micro-Flow pressure sensors LDE/LME/LMI in the range from 0 … 25 Pa to 0 … 50 mbar, alternatively as bidirectional version with ±25 Pa to ±50 mbar.

The Company

AMSYS GmbH & Co. KG is a medium-sized company from Germany that has specialized in innovative solutions in the field of sensor technology since its founding. As a sensor technology distributor, AMSYS is one of the leading specialists in pressure measurement technology in German-speaking countries.

The AMSYS product range includes piezoresistive pressure sensing elements, SMD-mountable transducers, amplified and unamplified as well as calibrated OEM sensors, PCB modules, and ready-to-use pressure transmitters. With sensors and pressure sensing elements covering a pressure range from 25 Pa to 800 bar, AMSYS provides solutions for a wide variety of applications. In addition, the portfolio includes OEM humidity sensors, temperature and inclination sensors, as well as wireless solutions for diverse use cases.

Thanks to the technical expertise of its employees and close collaboration with suppliers, AMSYS also offers customer-specific adaptations of standard products, delivering tailored problem-solving solutions.

Excellent features

- ultra-low pressure 0 .. 25 / ±25 Pa bis 0 .. 50 mbar / ±50 mbar

- high zero point accuracy due to thermal mass flow measurement

- high robustness against dust and deviations due to tube length by patented micro-flow principle (microstructured silicon chip)

- reflowable, for hose or manifold mounting

- additional digital temperature signal

- individually linearized, calibrated and temperature compensated